Encoders are vital components in motion control systems, converting mechanical movement into electrical signals that help monitor and control position, speed, and direction. Whether you’re working with industrial automation, robotics, or precision machinery, selecting the right encoder technology, optical, magnetic, or capacitive, can significantly impact system performance, reliability, and cost-efficiency.

Understanding the Encoder Types

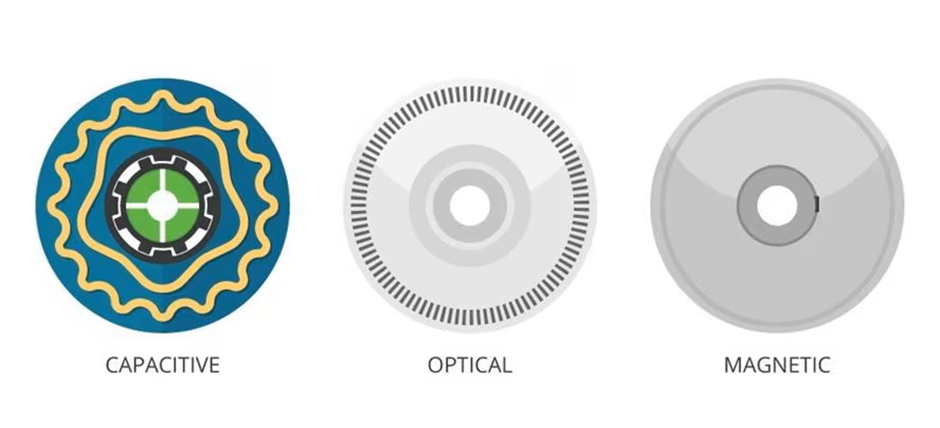

Before diving into comparisons, it’s important to understand how each encoder type works:

Optical Encoders

Optical encoders use a light source (typically an LED) and a photodetector to read patterns on a rotating disk. As the disk spins, the light beam is interrupted by transparent and opaque segments, generating a digital signal that corresponds to movement.

Magnetic Encoders

Magnetic encoders rely on magnetic fields to detect motion. A rotating magnet or magnetic strip interacts with a sensor, often a Hall effect sensor, to produce signals based on changes in magnetic flux.

Capacitive Encoders

Capacitive encoders measure changes in capacitance between sensor elements and a moving target. These changes are interpreted as position data. This technology is similar to how capacitive touchscreens work but adapted for motion sensing.

Differences between Types of Encoders

The key differences between optical, magnetic and capacitive encoders can be evaluated across several critical performance factors.

Accuracy and Resolution

- Optical Encoders offer the highest resolution and accuracy, making them ideal for applications requiring precise positioning, such as CNC machines and laboratory equipment.

- Magnetic Encoders provide moderate resolution, suitable for general industrial use where ultra-high precision isn’t critical.

- Capacitive Encoders deliver a good balance of resolution and accuracy, often sufficient for compact or embedded systems.

Environmental Resistance

- Optical Encoders are sensitive to dust, oil, and moisture. They perform best in clean, controlled environments.

- Magnetic Encoders are highly resistant to contaminants and vibration, making them suitable for harsh industrial settings.

- Capacitive Encoders are also resistant to dust and moisture and can operate reliably in challenging environments.

Durability and Robustness

- Optical Encoders are more fragile due to their reliance on optical components.

- Magnetic Encoders are rugged and can withstand shock, vibration, and temperature extremes.

- Capacitive Encoders are compact and durable, often with fewer moving parts, which enhances longevity.

Size and Integration

- Optical Encoders tend to be bulkier due to the need for precise alignment of optical components.

- Magnetic Encoders offer flexible mounting options and are available in compact designs.

- Capacitive Encoders are typically the smallest, making them ideal for space-constrained applications.

Cost

- Optical Encoders are generally the most expensive due to their high precision and complex design.

- Magnetic Encoders are more affordable and offer a good balance of performance and cost.

- Capacitive Encoders fall in the mid-range, offering cost-effective solutions for many applications.

Choosing the Right Encoder for Your Application

Selecting the right encoder depends on your specific operational needs. Here are key factors to consider:

Operating Environment

- If your system operates in a clean, temperature-controlled environment, optical encoders are ideal.

- For dusty, wet, or high-vibration environments, magnetic or capacitive encoders are better suited.

Precision Requirements

- For high-precision tasks like robotics, medical devices, or semiconductor manufacturing, optical encoders are the best choice.

- For general motion control in industrial automation, magnetic encoders offer sufficient accuracy.

- For embedded systems or compact devices, capacitive encoders provide a good compromise.

Budget Constraints

- If cost is a major factor, magnetic encoders offer reliable performance at a lower price.

- Capacitive encoders provide a balance between cost and capability.

- Optical encoders, while more expensive, may be necessary for applications where precision is non-negotiable.

Integration and Compatibility

- Consider the encoder’s output signal type (analog, digital, fieldbus) and ensure it matches your control system.

- Evaluate mounting options and physical dimensions to ensure seamless integration with your machinery.

Use Case Examples

- Industrial Automation: Magnetic encoders are commonly used in conveyor systems, packaging machines, and motor feedback loops due to their durability.

- Precision Robotics: Optical encoders are preferred for robotic arms and positioning systems where accuracy is critical.

- Consumer Electronics and IoT Devices: Capacitive encoders are ideal for compact, low-power applications like smart devices and embedded systems.

Choosing between optical, magnetic, and capacitive encoders is not a one-size-fits-all decision. Each technology has its strengths and trade-offs. Optical encoders deliver unmatched precision, magnetic encoders thrive in tough environments, and capacitive encoders offer compact versatility.

By evaluating your application’s environmental conditions, precision needs, budget, and integration requirements, you can select the encoder type that best supports your system’s performance and reliability.

At Transtech, we offer a wide range of heavy duty and industrial encoders from world-leading suppliers such as Baumer Hubner. Our heavy duty industrial encoders are engineered for robustness and precision, ensuring reliable operation even under the harshest conditions.

Need help on selecting the right encoder for you application?

Contact Transtech to speak with one of our specialists and we’ll help you to choose the right encoder or tailor one for your application.